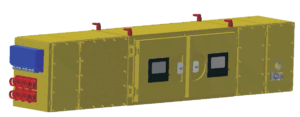

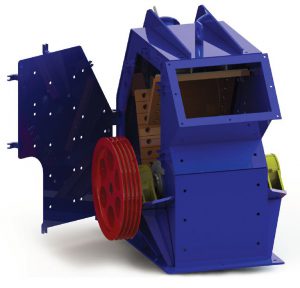

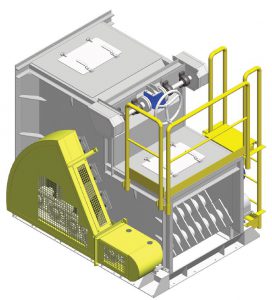

Flameproof multicontactor station type MCA-W is an energy distribution device designed for underground mining, to switching, protecting and control of electric drives of machines, supplied from three-phase alternating current network with voltage 6000VAC.

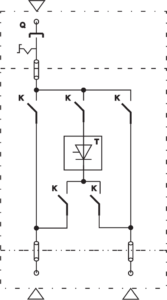

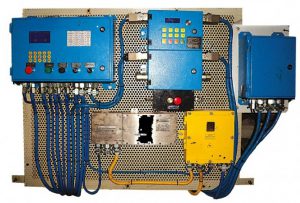

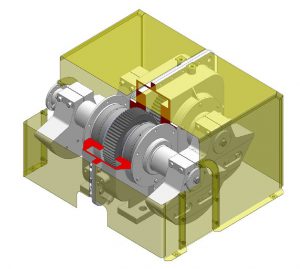

Station type MCA-W-1/2/0/c/1/A5/M is equipped with a thyristor block ensuring a soft start of the powered motors and bypass contactors for a direct start of the powered motor. Used mechanical locks electronic protection relays and controllers, ensure safe control of supplied mining devices. The station is equipped with buttons for parameter adjustment and local control as well as digital data transmission interface for remote control and data transmission with external system.

Flameproof multicontactor station type MCA-W was developed according to 2014/34/UE directive requirements and is intended for operation in underground excavations in potentially explosive atmospheres with methane and/or coal dust explosionhazard.

We encourage you to visit the detailed product offer: DOWNOLAD